Why Traditional Mechanical Jobs Are Shrinking—And What to Do About It

The Changing Reality of Mechanical Engineering

Ask your parents or professors about the “good old days” of engineering, and you’ll often hear stories of how Mechanical and Automobile Engineers were in high demand. A fresh graduate could join a design office, a manufacturing plant, or a maintenance department without much struggle.

Industries were expanding, factories were multiplying, and every company needed mechanical talent. Those were the golden years.

But the 21st century has completely changed that picture. Today, the same graduate often faces rejection after rejection. Despite having a degree, the opportunities don’t match the number of engineers entering the market.

So, what happened?

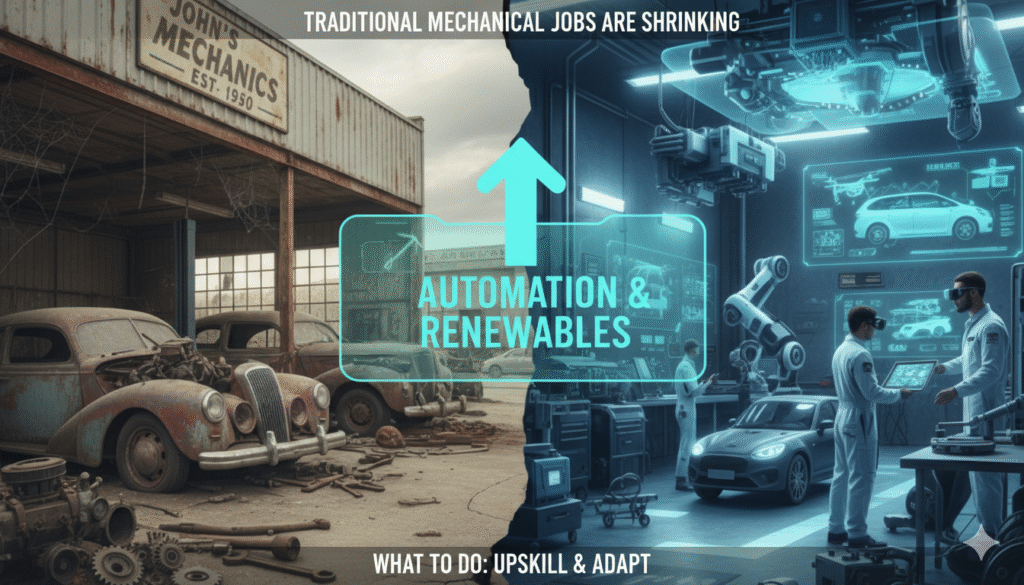

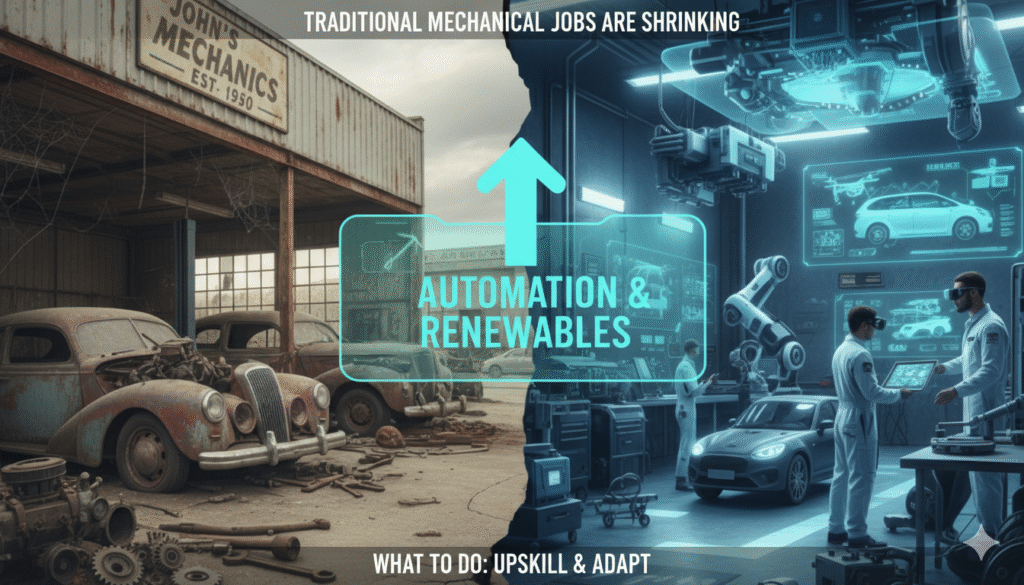

Why Traditional Mechanical Jobs Are Shrinking

The truth is simple: industries don’t run the way they used to.

- Automation & Robotics: Tasks that once required teams of engineers are now handled by automated machines.

- Artificial Intelligence: Predictive maintenance and design optimization have reduced the need for manual roles.

- Globalization & Outsourcing: Many routine design tasks are outsourced to low-cost centres worldwide.

This means routine jobs—design drafting, shop-floor supervision, maintenance checks—are disappearing.

And here’s the tough reality: a “general mechanical degree” that was valuable 30 years ago doesn’t guarantee a career today.

The Flip Side: Every Change Creates New Opportunities

Now for the good news: while traditional roles are reducing, new opportunities are being born in areas where technology, safety, and innovation come together.

One of the fastest-growing areas is Computer-Aided Engineering (CAE)—especially vehicle crash simulation.

Take the automotive industry for example. Car companies no longer rely on dozens of physical crash tests. Each crash test costs crores of rupees and destroys valuable prototypes. Instead, companies simulate hundreds of crash scenarios virtually using CAE tools like LS-DYNA, Hypermesh, and LSPP.

This shift has created a demand for a new kind of engineer: someone who understands mechanics and materials deeply, but can also apply that knowledge through advanced simulation tools.

Why Crash Simulation is Booming

Let’s put it in perspective.

- A frontal crash test of a new car in India costs around ₹2–3 crores.

- With LS-DYNA simulations, the same test can be run virtually, in hours, at a fraction of the cost.

- Engineers can test hundreds of crash conditions—from high-speed rollovers to child safety seat anchorage—without building multiple prototypes.

On top of that, global safety regulations like Euro NCAP, Bharat NCAP, and US NHTSA standards are becoming stricter every year. This means every OEM and Tier-1 supplier must invest heavily in virtual crash simulation.

In short: without CAE, the automotive industry cannot survive.

The Gap: Universities Aren’t Teaching This

Here’s the challenge—most mechanical graduates are still trained in traditional ways. Universities focus on thermodynamics, manufacturing, and theory, but rarely give exposure to tools like LS-DYNA or Hypermesh.

So, when freshers step into the real-world job market, they face a harsh gap:

- Jobs in manufacturing or maintenance are shrinking.

- Jobs in crash simulation and safety are booming.

- But they don’t have the skills to transition.

This is why many talented engineers feel stuck.

ELENO’s Role: Turning Engineers into Simulation Experts

This is exactly where ELENO Center of Excellence (ELENO COE) makes a difference.

Our approach is simple: Don’t prepare engineers for the past. Prepare them for the future.

At ELENO, we train students and working professionals in:

- LS-DYNA crashworthiness simulations – covering vehicle crash, seating systems, and impact scenarios.

- Hypermesh for advanced pre-processing and model building.

- LSPP for analyzing crash simulation results.

- AI for CAE – because the future of engineering isn’t just simulations, it’s smart, AI-driven simulations.

- Physics-driven learning – ensuring engineers understand “why” behind every simulation, not just “how.”

All this is delivered with mentorship from Nachiket Phadke, who brings 19+ years of hands-on crash simulation experience at the highest industry levels.

Our learners don’t just become software operators—they become industry-ready engineers capable of solving real-world safety problems.

Career Paths for CAE Engineers

Once engineers step into CAE and crash simulation, the career options expand dramatically.

Our trained learners are being hired by:

- Global OEMs like Tata Motors, Mahindra, Toyota, Mercedes-Benz.

- Tier-1 suppliers making seat systems, airbags, and other safety parts.

- Defense and aerospace industries, where crashworthiness and safety are critical.

And the benefits are clear:

- Higher salaries compared to routine jobs

- Greater long-term stability

- Global career opportunities

- The pride of working in vehicle safety engineering—a field that directly saves lives.

Real-World Example: Why India Needs Crash Simulation Engineers

India is the largest two-wheeler market in the world and one of the fastest-growing car markets. With the arrival of Bharat NCAP, automakers in India must now prove the safety of their vehicles.

This has already created a wave of demand for CAE engineers who can run crash simulations, optimize structures, and ensure compliance.

In short: if you have CAE expertise, India is one of the best places to build your career right now.

Final Word: Pivot, Don’t Panic

If you feel mechanical jobs are disappearing, don’t panic. The industry is not dying—it’s evolving.

The engineers who adapt, learn CAE, and master crash simulation will always be in demand. The ones who don’t… will keep struggling for shrinking roles.

At ELENO COE, we make sure you’re on the winning side of this shift. We train you to be part of the future of engineering—a future where physics, safety, and simulation come together.

Don’t prepare for the past. Prepare for the future—with CAE learning at ELENO.

📞 Contact Nachiket: 9881732144

🌐 Visit: www.eleno-elc.com