Beyond CAD: How Crash, Durability, and NVH Simulations are Saving Lives

In the world of engineering, CAD (Computer-Aided Design) is the glamorous first step. You sketch, model, and visualize beautiful components and sleek products. But let’s be honest — a 3D model might look great, but will it survive a crash? Will it last for 10 years? Will it ride quietly on rough Indian roads?

That’s where CAE (Computer-Aided Engineering) takes the front seat. Specifically: Crash, Durability, and NVH (Noise, Vibration, Harshness) simulations — the unsung heroes of product safety, reliability, and comfort.

These simulations are not just technical validations. They are life-saving tools.

CAD is for Form. CAE is for Survival.

Imagine a beautifully designed electric scooter. Slim, lightweight, trendy. But what if:

- The frame fails in a minor accident?

- The battery casing cracks over time?

- The ride feels like a tractor due to poor suspension NVH?

That’s a disaster waiting to happen — and the reason why simulations matter more than just looks.

Designing with CAE insights means your product can withstand, endure, and protect — whether it’s a vehicle, a structure, or a machine.

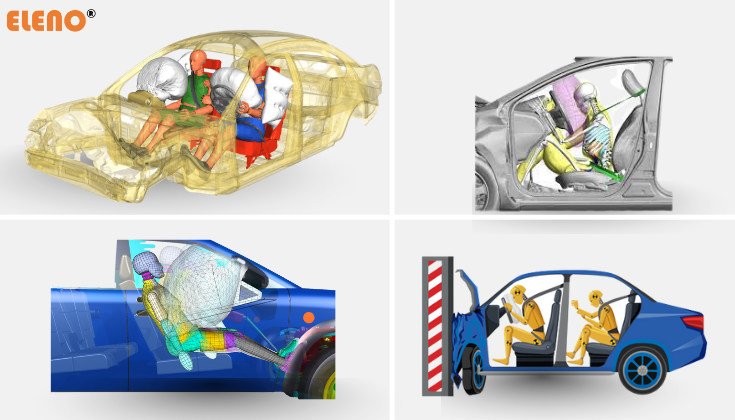

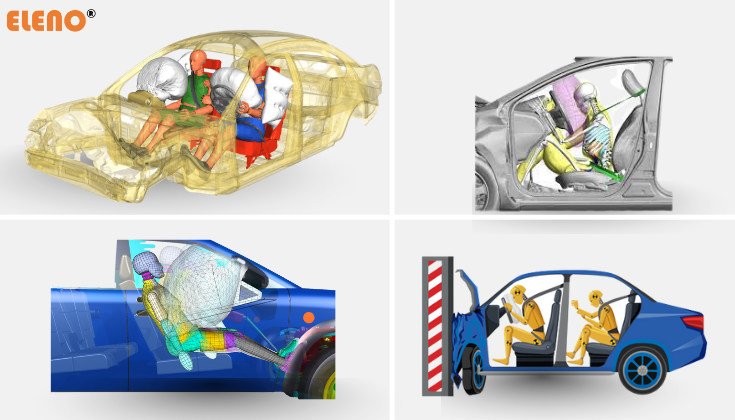

1️⃣ Crash Simulations – Designing for Life Protection

When a vehicle hits a pole or rolls over, it’s not just metal that bends — it’s lives at stake.

Crashworthiness simulations help us:

- Understand energy absorption in impacts

- Design crumple zones to protect occupants

- Ensure airbag and seatbelt timing

- Meet global safety standards like Global NCAP, FMVSS, EuroNCAP

Using tools like LS-DYNA, we simulate:

- Frontal, Side, Rear impacts

- Pedestrian protection

- Child seat interactions

- Vehicle-to-vehicle or barrier collisions

At ELENO COE, we’ve trained engineers who’ve worked on real crash projects where their simulation directly influenced how vehicles save lives.

2️⃣ Durability Simulations – Ensuring Long-Term Safety

A design that works today should also work after 1 lakh kilometers or 5 years in harsh weather.

Durability simulations analyze:

- Fatigue failure under repeated loading

- Weld and joint behavior under cyclic stress

- Corrosion-prone areas due to stress risers

- Structural degradation over time

Industries like automotive, railways, aerospace, heavy equipment, and consumer goods rely on fatigue and life estimation before launching a product.

Using tools like Abaqus, nCode, OptiStruct, engineers virtually test for millions of load cycles — reducing costly physical testing and warranty claims.

3️⃣ NVH Simulations – Engineering Comfort

Even the safest and most durable vehicle can be rejected if it sounds like a diesel truck when you accelerate.

NVH (Noise, Vibration, Harshness) simulation improves:

- Cabin comfort by reducing noise and vibration

- Engine mount and chassis design to isolate vibrations

- Wind and road noise attenuation

- Perception of quality through silent, smooth operation

Tools like Actran, Ansys Sound, LMS Virtual Lab, and HyperMesh NVH allow engineers to simulate how vibrations travel through structures — and how to stop them.

Comfort is not a luxury anymore. It’s a market expectation.

Why This Matters More in India

India has a unique mix of challenges:

- Rough roads

- Heavy loading conditions

- Unpredictable accidents

- Long usage cycles

That’s why Indian OEMs must focus more on CAE. It’s not just about launching a new model — it’s about launching one that protects and lasts.

At ELENO COE, our focus is on creating engineers who design with responsibility — not just to deliver a spec, but to protect a life.

Future of Engineering = CAE First, CAD Later

Designing just to “fit” or “look good” is not enough anymore.

Top global companies today follow a CAE-driven design approach:

- Run crash, fatigue, and NVH simulations on early design concepts

- Eliminate risky or unfeasible options quickly

- Use simulation data to drive CAD refinement

- Save time, material, money — and most importantly — lives

Final Words to Students and Parents

To students:

If you’re learning CAD, that’s a great start. But don’t stop there. Learn how to simulate and validate. That’s where the real engineering begins.

To parents:

Encourage your child to pursue core branches like Mechanical, Civil, Electrical, or Electronics, and let them explore Crash, Durability, and NVH simulation domains. These are future-proof, purpose-driven, and highly respected career paths.

To colleges:

Make your labs simulate real-world safety, not just shapes and assemblies. Bring in CAE tools that let students test their designs before they build.

Learn to Design for Safety, Reliability, and Comfort — Not Just Aesthetics.

At ELENO Centre of Excellence, we offer advanced training in Crashworthiness, Fatigue, and NVH Simulations, backed by industry projects and domain mentors.

We believe in creating engineers who understand what’s at stake — and simulate with a purpose.

📞 Contact Nachiket: 9881732144

🌐 Visit: www.eleno-elc.com